Ethyl Cellulose For Conductive Paste grade

CAS NO 9004-57-3

Appearance: white or off-white powder

Viscosity: 4-350cps in 2% solution

What is Ethyl Cellulose functions for Conductive Paste grade?

Ethyl Cellulose could be used in conductive pastes because it provides very low ash content, providing high purity and clean burn out for high-end electronic applications.it functions as a rheology modifier and as a binder and stabilizer for metal pigments. They burn out cleanly, leaving no residue after firing, so Ethylcellulose is a very perfect raw material for silver conductive paste application.

Ethyl Cellulose Features and benefits in Silver Conductive Paste application

- Thermal Stability

- Low Ash Content

- Stability to Light

- Thermoplasticity

- Good Water Resistance

- Excellent Binding

What other application Ethyl Cellulose Could be used for ?

- Paint, coating,printing inks

- Varnishes/Lacquers

- Pharmaceutical

- Food/Feed

- Personal care

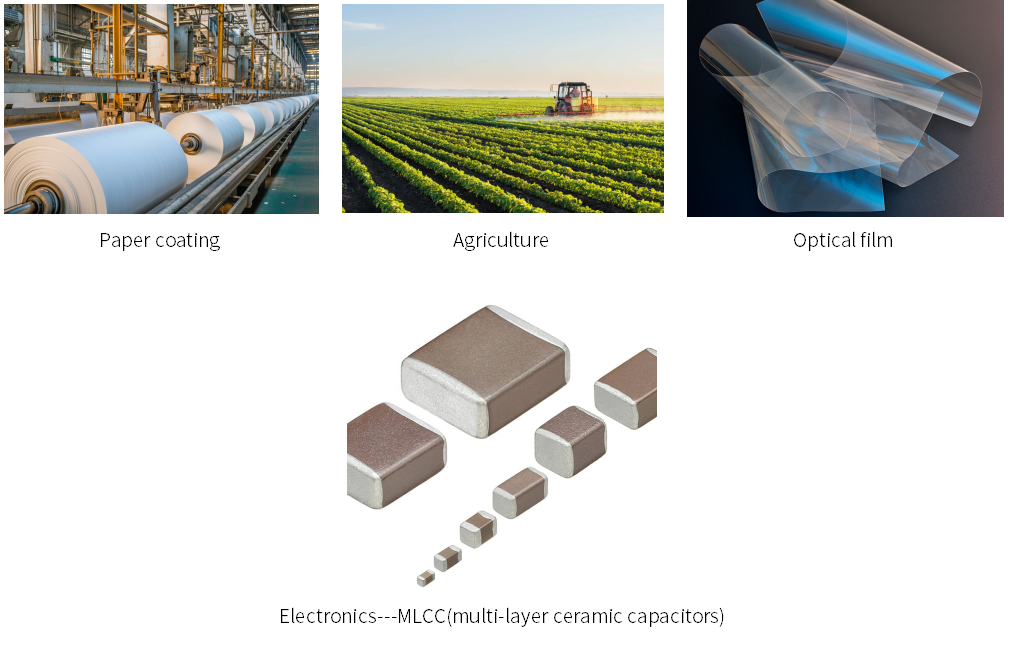

- Electronics---MLCC(multi-layer ceramic capacitors)

- Food packing

- Ceramics

- Conductive pastes

- Hot melts extrusion

- Paper coating

- Optical film

- Agriculture

Ethyl Cellulose Features and benefits in different application

- Thermal Stability

- Low Ash Content

- Stability to Light

- Thermoplasticity

- Good Water Resistance

- Excellent Binding

Ethyl Cellulose (EC) Powder spefication as below (table 1)

|

Specification |

Ethoxy Content,% |

||

|

K type |

N type |

T type |

|

|

Ethoxyl Content, % |

45.0-47.0 |

48.0-49.5 |

≥49.6 |

|

Viscosity(20℃at 25℃) mPa.s |

Complies with table 2 specification as below |

||

|

Solubility |

≧99.0 |

||

|

Ash,% |

≦0.3 |

||

|

Residue on ignition,% |

≦3.0 |

||

Ethyl cellulose Powder viscosity specification as below (Table 2)

|

Viscosity Type |

Viscosity,mPa.s |

Viscosity Type |

Viscosity,mPa.s |

|

4 |

3-5.5 |

70 |

62-78 |

|

7 |

6-9 |

100 |

90-110 |

|

10 |

9-11 |

110 |

100-120 |

|

15 |

12-18 |

150 |

135-165 |

|

20 |

18-24 |

200 |

180-220 |

|

35 |

30-39 |

250 |

220-270 |

|

50 |

45-55 |

300 |

270-330 |

|

55 |

51-61 |

350 |

250-385 |

Package

Storage

During Storage, please have to protect the product contact with moisture,prolonged storage at temperature above 30℃,carefully store it in a warehouse that provides cool and dry conditions.