Printing and Inks Grade EC

Ethyl Cellulose (EC) Features and benefits in Print and Inks applications

- Gravure ink

- Flexographic ink

- screen printing

- Heat Transfer print

What application need Ethyl Cellulose?

- Paint, coating,printing inks

- Varnishes/Lacquers

- Pharmaceutical

- Food/Feed

- Personal care

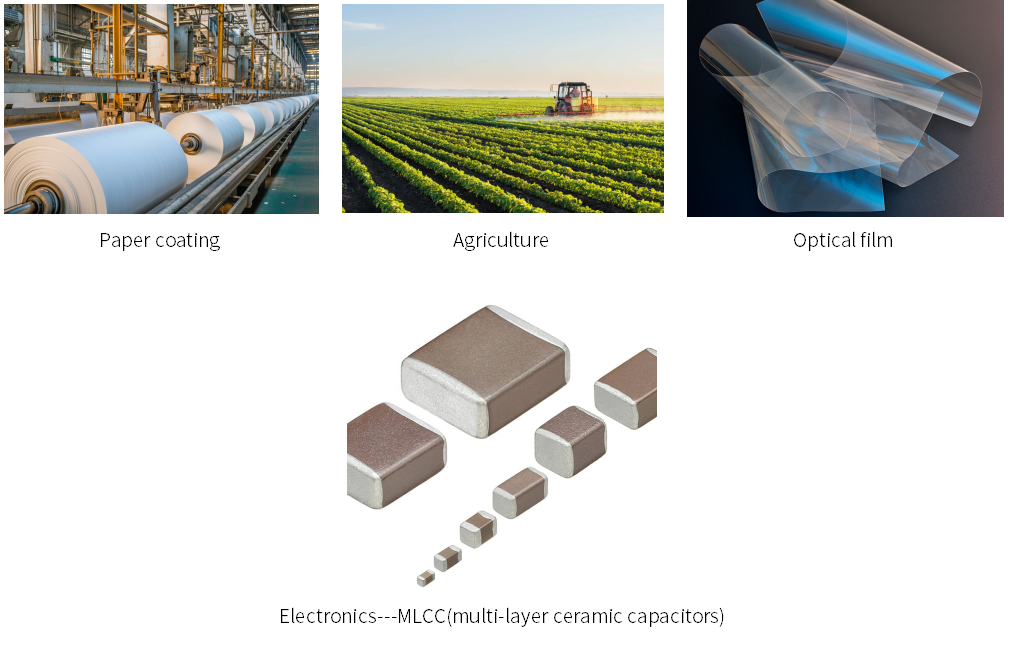

- Electronics---MLCC(multi-layer ceramic capacitors)

- Food packing

- Ceramics

- Conductive pastes

- Hot melts extrusion

- Paper coating

- Optical film

- Agriculture

Ethyl Cellulose Features and benefits in different application

- Thermal Stability

- Low Ash Content

- Stability to Light

- Thermoplasticity

- Good Water Resistance

- Excellent Binding

Ethyl Cellulose (EC) spefication as below (table 1)

|

Specification |

Ethoxy Content,% |

||

|

K type |

N type |

T type |

|

|

Ethoxyl Content, % |

45.0-47.0 |

48.0-49.5 |

≥49.6 |

|

Viscosity(20℃at 25℃) mPa.s |

Complies with table 2 specification as below |

||

|

Solubility |

≧99.0 |

||

|

Ash,% |

≦0.3 |

||

|

Residue on ignition,% |

≦3.0 |

||

Ethyl cellulose viscosity specification as below (Table 2)

|

Viscosity Type |

Viscosity,mPa.s |

Viscosity Type |

Viscosity,mPa.s |

|

4 |

3-5.5 |

70 |

62-78 |

|

7 |

6-9 |

100 |

90-110 |

|

10 |

9-11 |

110 |

100-120 |

|

15 |

12-18 |

150 |

135-165 |

|

20 |

18-24 |

200 |

180-220 |

|

35 |

30-39 |

250 |

220-270 |

|

50 |

45-55 |

300 |

270-330 |

|

55 |

51-61 |

350 |

250-385 |

Package

Storage

During Storage, please have to protect the product contact with moisture,prolonged storage at temperature above 30℃,carefully store it in a warehouse that provides cool and dry conditions.